![]()

|

|

This repair requires timing and other adjustments and should be done by a Melco authorized service technician. |

When installing the x-drive cable it is extremely important that you do not damage the protective coating of the cable, ensure that the windings on the cable spool is correct, that the cable is correctly tensioned, and the installation is done precisely as provided in these instructions.

When replacing the x-drive cable it is strongly recommended that the x-drive cable assembly be ordered and installed. The precision windings and lengths of the cable extending from the spool is critical and is best done only at the factory.

|

|

CAUTION!! Use extreme care to avoid damaging the protective coating on the x-drive cable. If the coating is damaged, the cable will eventually fray and/or corrode. |

|

|

CAUTION!! At any time when the machine is either powered down or in E-Stop mode, neither the X- nor Y-carriage should be moved at a high rate of speed. If there is a desire to manually move either carriage, it should be pushed or pulled GENTLY to prevent serious damage to the main control board. |

Replacement Parts Needed:

x-cable assembly (x-cable prewound on spool)

Order replacement other replacement parts if needed, such as pulleys

Replacement hardware if any screws or nuts are stripped

X-Cable Assembly Installation:

1. Remove the old x-drive cable assembly.

2. Make sure the x-carriage is positioned all the way to the right at a hard stop.

Figure 1 - X-Cable Spool

(Taped and Installed)

|

|

CAUTION!! DO NOT remove the tape from the x-cable spool when you install it until the cables are tightened up. The cable will become unwound and will be extremely difficult to rewind with the precise lengths needed to install it on the machine. |

3. Install the x-cable spool on the x-motor shaft with a 5x0.8mm bushing, four 8mmIDx18mmOD external star washers, .173IDx.375OD D-Shaped washer, and M4x10mm cap head socket screw. Tighten the screw to 8 in-lbs of torque using a reliable torque wrench with .075" hex bit.

Figure 2 - Right Rear Pulley

4. Run the cable through the cable around the left pulley located by the cable channel on the far left edge at the rear of the sewing head.

Figure 3 - Right Beam Cable Pulleys

(Arrows indicate direction of cable to the front)

5. Run the cable through the through hole in the back of the sewing head to the right rear carriage cable pulley down to the top right beam cable pulley.

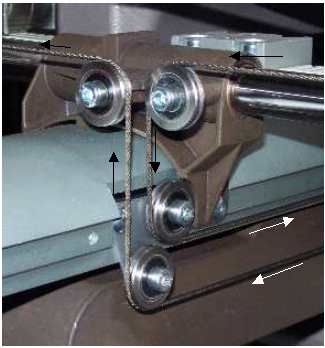

Figure 4 - Center Beam Cable Pulleys

(Arrows indicate direction of cable to the front)

6. Run the cable from the top right beam cable pulley around the right center beam cable pulley to the bottom right beam cable pulley.

7. Run the cable around the bottom right beam pulley (see figure 3), around the right front carriage pulley into the cable access hole to the front of the machine.

Figure 5 - X-Cable Clamp

8. Pull the slack out of the right cable and wrap it twice around the cable clamp and tighten the cable clamp screws to 11 in-lbs of torque using a reliable torque wrench with a .075" hex bit tensioning the right cable until all the slack is removed from it.

Figure 6 - Left Rear Cable Pulley

9. Run the left cable from the spool around the left rear cable pulley.

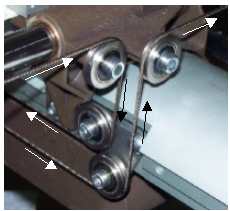

Figure 7 - Left Beam Cable Pulleys

10. Run the cable from the left rear cable pulley, around the left rear carriage pulley down to the left top beam pulley around the left center beam pulley (See Figure 4), around the left bottom beam pulley up and around the left front carriage pulley.

11. Run the cable through the cable access hole on the left side of the machine to the front.

Figure 8 Cable Tensioning Bracket

(Left side of machine)

12. Install two 5.3IDx15ODx1.2mmTHK fender washers with a cable tensioner compressing spring on the tensioning bolt and insert it into the tensioning bracket. Attach a M4x0.7 nylock hex nut. Hold the cable in position around the bracket mounting screws as shown in Figure 8 above and tighten the hex nut so that the preload to the spring is such that the distance from the outside edges of the fender washers is 22mm±1mm.

13. Tension the x-cable using the procedures prescribed in "X-Cable Tensioning".

13. Install the upper arm back cover.

14. Install the left and right transparent arm covers.

15. Install the left and right upper arm covers.