The rotary hook support may need to be adjusted if a garment gets caught in the rotary hook or if it is struck too forcefully with a hoop as the hoop is being loaded onto the machine. It may also need to adjusted if the screws securing it are accidently loosened.

If the rotary hook support gap is too large or too small, it will cause sewing issues.

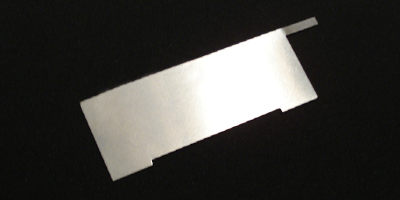

To inspect and adjust the rotary hook support gap, you will need the Hook Retaining Finger Gauge (PN:009027-01).

Inspect the Rotary Hook Support Gap

- Remove the bobbin case.

- Remove the rotary hook guard by loosening the two button head screws securing it and sliding it away from the machine.

- Remove the needle plate by removing the two allen screws that secure it.

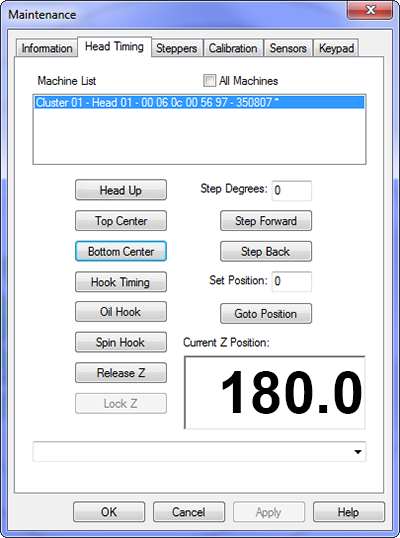

- In AMAYA OS, go to > > and the tab.

- Click on .

This will bring the needle down very quickly.

- Inspect the left to right position of the hook support as it aligns to the needle. It should be center left to right. If not, it may be necessary to form the hook support to the correct alignment. If this is not possible, you may need to replace the hook support (PN: 33046).

- Once the left to right position of the hook support is correct, click the button and then click .

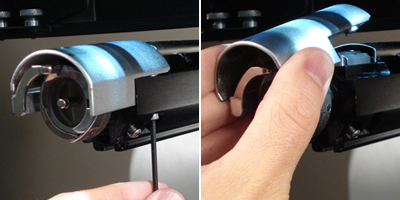

- Insert the retaining finger gauge between the hook support and the hook basket.

If the gauge does not slide in easily, do not force it. You may scratch the highly polished surface of the hook support or hook basket, resulting in thread breaks.

The retaining finger gauge should slide between the hook support an the hook basket with no resistance. The gap between the hook support and the hook basket should be no more than 1.1 times the thickness of the gauge. (The gauge is 0.020', and the tolerance is +/- 0.002') -

The tip of the hook support should be flush with the top of the hook basket.

-

If the adjustment is not correct, adjust the rotary hook support with the procedure below.

Adjusting the Rotary Hook Support

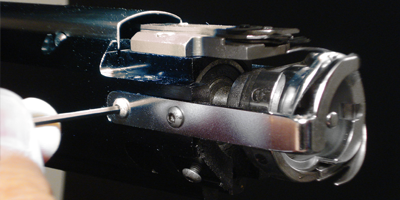

- Use an allen wrench to loosen the two screws holding the hook support.

- Insert the gauge between the hook support and the hook basket.

- Holding the hook support from the side with the adjustment screws, adjust the position of the hook support to the requirements from the inspection procedure above.

- Remove the gauge while holding the position of the hook support. Make sure that the tip of the hook support is no higher than the hook basket.

- Tighten the two screws holding the hook support.

- Verify that the gauge still slides freely between the basket and the hook support.

- Reinstall the rotary hook guard.

- Reinstall the needle plate.