The most common sign that pinch rollers need maintenance is that the thread will walk to the side of the roller and create a "bird's nest". This is typically flagged by the software as a thread break, but when you look at the top thread, it doesn't appear to be broken. However, when you look under the cloth, you find a mass of thread under the needle plate.

Maintaining these rollers is part of the normal maintenance timers, but if you are experiencing trouble with bird-nesting, clean and grease the rollers.

Cleaning & Greasing the Pinch Rollers

To clean and grease the pinch rollers,

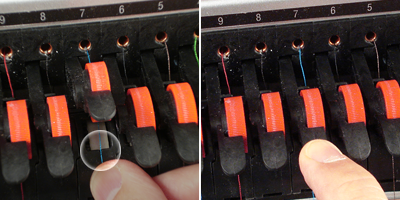

- Lift the thread feed arm.

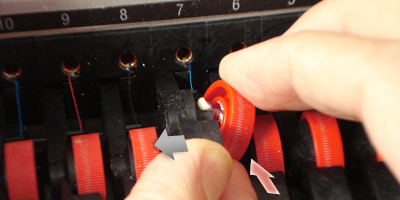

- With one hand, steady the lever. With the other hand, pull the pinch roller to the right and off of the hub.

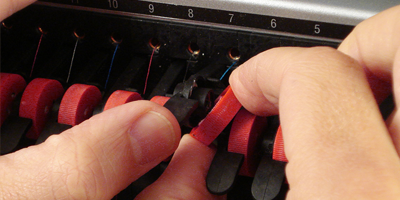

- Next, with the roller tilted, pull the arm slightly to the left and pull the roller straight out from the machine. The arm has a small amount of flex to it, but if pulled too far to the left, it can be damaged.

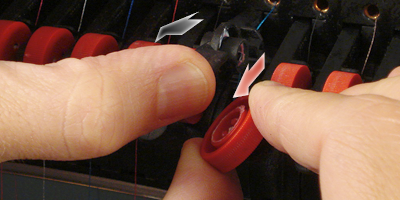

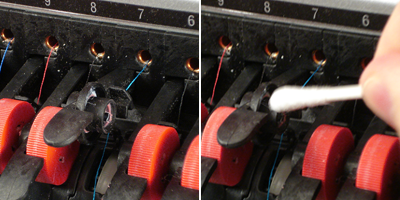

- With a cotton swab, clean both the hub and the pinch roller. Take care to avoid getting grease on the pinching surface of the roller.

- Apply EMB Polymer grease to the top surface of the hub and on the outer surface of each of the three tabs inside the pinch roller.

- With the roller tilted, pull the arm slightly to the left and reinsert the roller straight into place.

- Tilt the roller back up. Gently rotate the roller to help spread the grease before snapping it into place.

- Press the roller to the left to snap it into place.

- Line the thread up with the v-notch on the thread feed gear cover and press the pinch roller arm back down.