Thread trimmings and lint buildup can cause thread breaks and misstrims. Cleaning beneath and ensuring that the needle plate is centered can prevent these frustrations.

Cleaning Under the Needle Plate

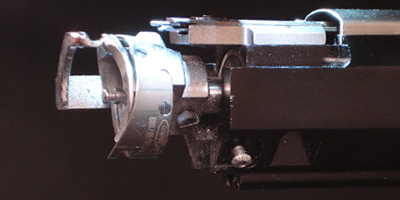

- Remove the bobbin case.

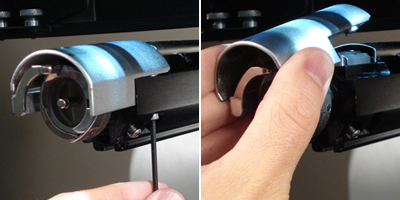

- Remove the rotary hook guard by loosening the two button head screws securing it and sliding it away from the machine.

- Remove the needle plate by removing the two allen screws that secure it.

- Using compressed air of a brush, remove any thread or lint buildup from the area.

- Reinstall the rotary hook guard.

- Reinstall the needle plate.

Center the Needle Plate

- Center the needle plate as best you can by feel and by eye.

- Lower the needle to its bottom most rotation.

- This can be done manually by pressing the e-stop and rotating the z-shaft to control the decent of the needle,

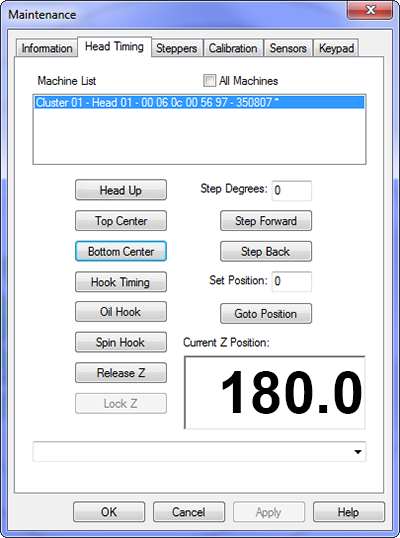

- OR by going to > > and the tab. Then clicking on .

This will bring the needle down very quickly.

- With the needle lowered, loosen the screws securing the needle plate, and center the hole in the needle plate around the needle.

- Tighten the screws securing the needle plate.

- Depending on the method used to lower the needle, raise it back up by releasing the E-stop or clicking on and .