Embroidery quality can be greatly effected by your choice of needles. You will need to find what works best with your applications. The following information should help.

AMAYA machines utilize DBxK5 needles. Among other things, this means that they are industrial needles with nearly 25% larger eyes.

Needle Sizes

Needles come in a variety of sizes, and most are marked with two numbers. For example, you will find 75/11 needles. The first number is metric and is the diameter of the needle blade. It is measured in hundredths of a millimeter. A 75/11 needle has a blade that is 0.75mm in diameter.

Standard sewing conditions will utilize needle sizes ranging from 65/9 to 80/12 needles.

Smaller needles work well for finer materials, thinner threads, and delicate detail work.

Larger needles work well for tougher and more abrasive materials. As the holes made by the needle are larger, sewing creates less friction on the threads and helps prevent thread breaks.

| Size | Benefit | Drawback |

| 60/8 | Used for the thinnest threads and finest detail work. | Thinner needle blade is more prone to needle deflection and breakage. Uncommon needle size and can be difficult to source and purchase. |

| 65/9 | Smallest of the more common needles. Used for fine fabrics, 60-weight thread, and delicate design details and tiny lettering. | Thinner needle blade is more prone to needle deflection and breakage. |

| 70/10 | Used for fine fabrics, design details and small letter. Good needle size for a larger majority of embroidery work. | Thinner needle blade is more prone to needle deflection and breakage. |

| 75/11 | Standard needle size and good for the majority of embroidery applications. | May be too large for finer detail work. |

| 80/12 | Largest of the more common needles. Often used caps with buckram backing or cotton duct jackets to help alleviate thread breaks. | Larger holes can damage finer materials and smaller design details. |

| 90/14 | Used with some specialty and metallic threads. | Larger holes can damage finer materials and smaller design details. Uncommon needle size and can be difficult to source and purchase. |

| 100/16 | Used with the thicker 12-weight threads like the wool-acrylic blends. | Larger holes can damage finer materials and smaller design details. Uncommon needle size and can be difficult to source and purchase. |

Needle Points

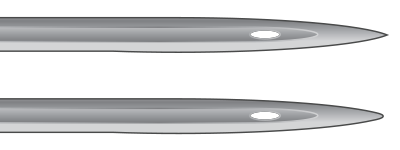

Needle points also come in a variety of options. The main two are sharp and ball point.

Sharp point needless are generally better at cutting through materials and are usually used on tightly woven or non-woven.

Ball point needles are most often used on knit materials. They tend to move the threads of the material to the side of the needle as they sew. Ball point needles are usually marked with a "BP" on the package.

Needle Coatings

Needles are offered with a few different coatings.

Standard needles are silver in color and offer a sewing life of approximately 4 to 6 solid sewing hours.

Titanium needles are gold in color and offer an extended sewing life of 2 to 3 times the life of a standard needle. While they are stronger needles, they have little flex. If deflected, they will often break instead of bend. Titanium needles are usually marked with a "PD" on the packaging.

Other needle coatings exist the cut down on the heat built up when traveling through synthetic materials.